Coatings Institute Newsletter Volume 5 Issue 2

What’s Happening at Missouri S&T:

(formerly UMR)

On January 1, 2008 the University of Missouri-Rolla (UMR) , changed its name to Missouri University of Science and Technology (Missouri S&T) . The new name more accurately describes the university’s true focus. Missouri S&T was founded in 1870 as the first technological university west of the Mississippi River. The original name was Missouri School of Mines and Metallurgy. In 1964 the university was re-named the University of Missouri-Rolla in an effort by the state of Missouri to consolidate the names of the four campuses which form the University of Missouri system. The name change does not change the excellent educational programs at Missouri S&T but helps students identify the university as a technological and science based campus. Missouri S&T has been increasing its enrollment over the past 5 years from less than 5,000 to over 6,000 students and a has planned an increase to over 7,000. The UMR Coatings Institute is now the Missouri S&T Coatings Institute.

**All our web sites and e-mail addresses have also changed. In the past they were @UMR.EDU but now they are @MST.EDU. Our UMR domain and e-mail address will be retired as of the end of next month (July 08) so please update your records accordingly with our new e-mail (coatings@mst.edu) and web address, http://coatings.mst.edu/. Our university's new spam filter is also fairly aggressive, so if you e-mail us and do not get a response within a few days, please e-mail again or call us.

Summer 2008 Short Course

Summer 2008 Short Course - "Introduction to Coatings Composition and Specifications"

** Register Today - Some Spaces Still Available!!!**

This summer we will be offering "Introduction to Coatings Composition and Specifications" July 23-25, 2008, in Rolla, Missouri, a course designed for the new coatings person in areas such as sales, marketing or production. The course was initiated by a number of raw material companies and distributors requesting a course with this format. This course is not as heavily technical as is our “Basic Composition of Coatings" and “Introduction to Paint Formulation" courses. The ?Introduction to Coatings Composition and Specifications" course is a two and a half day course which will discuss the types of coatings, the basic composition of coatings and the tests and specifications used by the industry. This course will allow the participant to gain the fundamentals needed to work in this industry and to communicate more clearly. More information can be found at the above links, on our website at http://coatings.mst.edu/, by e-mailing coatings@mst.edu or by calling 573-341-4419.

Fall Short Course Dates

This fall we will be offering ?Basic Composition of Coatings" September 15-19, 2008. The Basic Composition course is intended for new personnel in the coatings profession. It targets the components of coatings (resin, pigments, extenders, solvents and additives), testing and specifications, general formulation and manufacturing methods. Basic Composition is primarily a lecture course with several laboratory demonstrations. For more information see our web site at http://coatings.mst.edu/index.html and to register contact Michael Van De Mark at coatings@mst.edu or call 573-341-4419. **This course is held on the Rolla campus**

This fall we will be offering ?Introduction to Paint Formulation" November 3-7, 2008. This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work. For more information see our web site at http://coatings.mst.edu/ and to register contact Michael Van De Mark at coatings@mst.edu or call 573-341-4419. **This course is held on the Rolla campus**

American Coatings Show

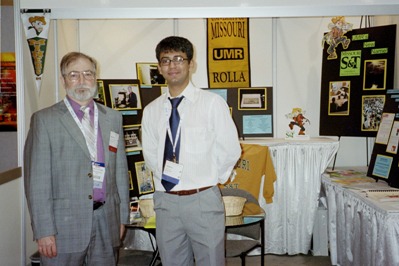

We would like to thank everyone who stopped by to visit with us at our booth at the American Coatings Show! If anyone has any questions about our short courses, our academic program, or about working with us on projects or research, we would be happy to answer them, please feel free to e-mail or call us.

|

| Dr. Michael Van De Mark, Director and Jigar Mistry, Graduate Student |

Thank you to everyone who entered our sweatshirt drawing! The winner this year was:

*Andrew DeVuyst, Angell-Demmel

We look forward to seeing you all at next year's show!

Technical Insights on Coatings Science

Nanoscale Pigments

By Brooke Burroughs, Senior Undergraduate Polymer and Coatings Science Chemistry Major, Missouri S&T Coatings Institute

Nanotechnology is currently the most popular field of study for a wide variety of industries (1). These industries include but are not limited to aerospace, agriculture, security, energy, information technology, medicine, transportation, consumer products, and environmental improvement (1). Yet, nanoscale particles have been used in the coatings industry for many years. The nanoscale region is classified as a particle less than 100nm (1). For coatings, a nanoscale pigment is normally less than 30nm. The particle size and shape, size distribution, pigment volume concentration, and pigment distribution in the medium are all important properties that could affect the performance of the pigment (2). The term performance here includes hue, color purity, tinting strength, transparency, and hiding power of the pigment (2).

The nanoscale pigments CoAl2O4, Cr2O3, ZnCo2O4, (Ti0.85Ni0.05 Nb0.10)O2, a-Fe2O3, and Cu(Cr, Fe)O4 contribute to the colors blue, dark green, green, yellow, red, and black, respectively (3). These nanoscale pigments have a dual purpose of adding UV-stability while also adding coloring to materials such as plastics, inks, transparent thin films on glass, and coatings on luminescent materials. The very large surface-to-volume ratios and low temperatures needed for the correct crystalline structure causes complications with the above pigments’ synthesis. One process used to synthesize nanoscale pigments is the polyol process. In this method, diethylene glycol is used to complex and stabilize the surface of the oxide particles, CoAl2O4, Cr2O3, ZnCo2O4, (Ti0.85Ni0.05 Nb0.10)O2, a-Fe2O3, and Cu(Cr, Fe)O4. The polyol method produces nanoscale pigments suspended in high boiling point alcohols that are colloidally stable. The solids content can be as high as 20% by weight. A centrifuge is used to separate the pure pigment powder from the suspension. The pigment powders are crystallized with temperature range from 180 to 240°C. The reflection curves of the prepared pigments showed a steep increase corresponding to a brilliant body color. Scanning electron microscopy showed the pigments were a spherical shape with the average diameter being 50 to 100nm. The pigment diameter was dependent upon the experimental conditions (3).

The following pigments’ color qualities were changed by narrowing the size distribution to nanoscale: BaSO4, lithopone (mixture of BaSO4 and ZnS), CdS, cadmium yellow (mixture of CdS and ZnS), a-Fe2O3, Fe3O4, CoFe2O4, cobalt green (ZnCo2O4 with a zincite-type structure doped with cobalt), Cr2O3, BaCrO4, and PbCrO4 (2). These monodispersed nanoscale inorganic pigments were synthesized using the liquid-solid-solution (LSS) phase transfer and separation process (2). The LSS process is useful since nanocrystals can be formed with varied properties such as semiconducting, fluorescence, magnetic, and dielectric (4). The LSS synthesis method reduces the metal ion by ethanol at the interface of metal linoleate, ethanol-linoleic acid liquid phase, and the water-ethanol solution at different specified temperatures. The aqueous solution of metal ions, sodium linoleate, and the mixture of linoleic acid and ethanol are added respectively into a vessel. This causes a separation of the three phases; the metal ions spontaneously undergo a phase transfer process with the interface of the sodium linoleate and the water-ethanol solution. The phase transfer leads to the formation of the metal linoleate and sodium ions into the aqueous phase. The ethanol in the liquid and solution phase reduces the metal ion at the liquid-solid or solution-solid interface at the specified temperature. The metal is reduced and linoleic acid is absorbed on the surface of the metal nanocrystals with the alkyl chains on the outside. The nanocrystals now have a hydrophobic surface. The nanocrystals spontaneously phase separate from the solution due to the weight of the metal and the incompatibility between the nanocrystals hydrophobic surface and their hydrophilic surroundings (4).

The a-Fe2O3, Fe3O4, CoFe2O4, cobalt green (ZnCo2O4 with a zincite-type structure doped with cobalt), and Cr2O3 pigments produced by the LSS method generally could not be synthesized below 160°C (2). The a-Fe2O3 had a square-plate shape with dimensions less than 10nm and self-assembled into ordered 2D arrays. The Fe3O4, CoFe2O4, cobalt green (ZnCo2O4 with a zincite-type structure doped with cobalt), and Cr2O3 pigments were usually round in shape with diameters of 5, 5, 4, and 10nm, respectively. The BaSO4, lithopone, CdS, and cadmium yellow can be prepared at any temperature below 200°C including room temperature. These pigments were synthesized at 160°C and had average diameters of 6nm for BaSO4, 5nm for lithopone, 4nm for CdS, and 2.5nm for cadmium yellow. The wide range of temperatures and narrow size distribution makes BaSO4, lithopone, CdS, and cadmium yellow very important for industrial applications due to low cost. At 70°C, the BaCrO4 and PbCrO4 pigments had diameters of 9-11nm. The a-Fe2O3, Fe3O4, CoFe2O4, cobalt green (ZnCo2O4 with a zincite-type structure doped with cobalt), and Cr2O3 pigments have many advantages including being able to coat glass plates by spraying, dripping, or spin coating with compact particle layers (2).

The color qualities of the pigments synthesized by LSS were measured quantitatively by the use of visible absorption spectra (2). The spectra proved the pigments had very pure and brilliant colors. One drop of the cadmium yellow nanoparticles with a concentration of 0.1g pigment to 20mL cyclohexane sufficiently dyed a 4 by 4cm2 white cloth. The cloth did not fade even after the cyclohexane evaporated and the cloth was washed with water. All of the pigments in this study have strong tinting strength (2).

Another nanoscale pigment of interest is titanium dioxide. Titanium dioxide pigments can be used as UV-absorbers and to obtain color effects in coatings (5). Nanosized titanium dioxide has problems with photoactivity due to the higher surface area in comparison to non-nanosized pigments. The titanium dioxide nanocrystals are doped with other elements and undergo surface treatments with layers of inorganic substances to increase the UV resistance. One study showed that 12% by weight of aluminum oxide post-treatment was needed to inhibit the photoactivity of a titanium dioxide particle with a diameter of 20nm. Titanium dioxide commonly used as a white pigment, approximately 240 nm, will scatter all wavelengths of the visible spectrum. Nanoscale titanium dioxide particles were first developed as transparent UV protectors but some will scattered blue light. Due to this unique property, these nanoparticles can be used in metallic coatings to give desired color effects (5).

With the wide use of nanoscale particles, the need to investigate the interactions with the environment and humans becomes very important. Titanium and zinc oxides are very common in such studies since they are used in household products including sunscreen. Titanium, silica, and zinc oxides are used frequently due to their greater surface area than other nanoscale particles (6). Many studies have confirmed that titanium oxide is toxic to both Gram-negative and Gram-positive bacteria. In this study, titanium oxide reduced the growth of B.subtilis by 99% at a concentration of 2000ppm and the growth of E. coli by 72% at a concentration of 5000ppm. Micro-sized bulk silica oxide has shown lack of toxicity to bacterial growth; however, the study by Adams, Lyon, and Alvarez showed that nanoparticle silica oxide does have some toxic affects to bacterial growth. Silica oxide was the least toxic of the other two nanoparticles tested. At the highest concentration of 5000ppm, silica oxide reduced the B.subtilis growth by 99%. Zinc oxide has shown more antibacterial activity with Gram-positive B.subtilis than with the Gram-negative E. coli. The zinc oxide nanoparticles decreased the growth of B.subtilis by 90% and the growth of E.coli by 48% (6).

A few synthesis methods and various advantages and disadvantages of nanosized pigments have been discussed. Nanoparticles have interesting properties due to their high surface area that can be both beneficial and a downfall. Nanosized pigments have great potential to create brilliant color effects but could be harmful to the environment and humans. More research needs to be done to clarify nanosized pigments interactions with their surroundings.

References

1. Gulson, B., Wong, H. “Stable Isotopic Tracing-A Way Forward for Nanotechnology.” Environmental Health Perspective, 114, 10, 1486-1488, 2006.

2. Wang, Dingsheng, Liang, Xin, and Li, Yadong. “Preparation of Nearly Monodisperse Nanoscale Inorganic Pigments.” Chem. Asian J. (2006), 1-2, 91-94.

3. Feldmann, Claus. “Preparation of Nanoscale Pigment Particles.” Advanced Materials (Weinheim, Germany) (2001), 13(17), 1301-1303.

4. Wang, Xun, Zhuang, Jing, Peng, Qing, and Yadong, Li. “A general strategy for nanocrystal synthesis.” Nature Letters. (2005), 437, 121-124.

5. Winker, Jochen. “Nanoscaled Titanium Dioxide- Properties and Use in Coating with Special Functionality.” Macromolecule Symp. (2002), 187, 317-324.

6. Adams, Laura, Lyon, Delina, Alvarez, Pedro. “Comparative Eco-toxicity of Nanoscale TiO2, SiO2, and ZnO water suspensions.” Water Research. (2006), 40, 3527-3532.