What’s Happening at Missouri S&T (formerly UMR):

SHORT COURSE DATES

We will be offering "Introduction to Paint Formulation" May15-19 (Spring 2017). This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work.

For more information see our web site at http://coatings.mst.edu and to register contact us at mstformulation@mst.edu or call 573-341-4419. **These courses are held on the Rolla Campus**

ONLINE SHORT COURSE

We are offering "Introduction to the Coating Systems" online short course. This course is targeted for automotive and aviation type OEM companies. This self-paced seminar will cover the painting system from the composition of paints to the evaluation of the dry film. The pigments, resin, solvents and additives will be discussed including their influence on the coatings performance. Color measurement, surface profile, and other evaluation criteria will be related to composition. The importance of surface preparation and other manufacturing criteria will show the system complexity and each step's importance.

We are offering "Surface Defects: Elimination from Human and Process Contaminants" online short course. This course addresses many of the issues in prevention and minimization of defects. The course covers the defects caused by the coatings process, as well as human issues, including personal care product causes. Several of the surface defects are discussed – from basic principles and real world automotive and aircraft examples. The highly practical approach of this course will greatly aid the personnel involved in the painting operation to reduce and systematically approach issues.

EMPLOYMENT TAB

We have started an employment section for our students and companies. We have a full time job section, an intern / co-op section and a graduating and alumni students section . Please explore our section on employment on our web site. Anyone wanting to have job opening listed, please contact us at (573) 341-4419 or e-mail: mstformulation@mst.edu . You can also write to us at Missouri S&T Coatings Institute, BOM #2, 651 W. 13th St., Rolla, MO 65409-1020. Our web site is http://coatings.mst.edu

TECHNICAL INSIGHTS ON COATINGS SCIENCE

How to measure the Appearance of the Coating? – Part - I

Ashish Zore, Missouri S&T Coating Institute

- Gloss

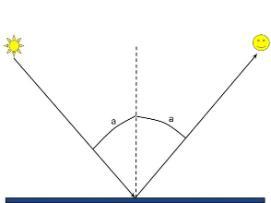

High gloss – Gloss is high when the angle of incidence is equal to the angle of reflection. Smooth and highly polished surfaces reflect images distinctly i.e. most of the incident light is directly reflected in a direction of angle of reflection [1].

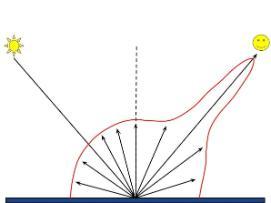

Matte to Semi-gloss – Rough surfaces diffusely scatter the light in all directions which diminished the image forming ability of the surface. The reflected images appear blurred. The more uniform the scatter, the less intense is the reflection in the main direction (i.e. at the angle of reflection) [1].

High gloss – specular reflection Matt – Semi gloss – diffused or scattered reflection

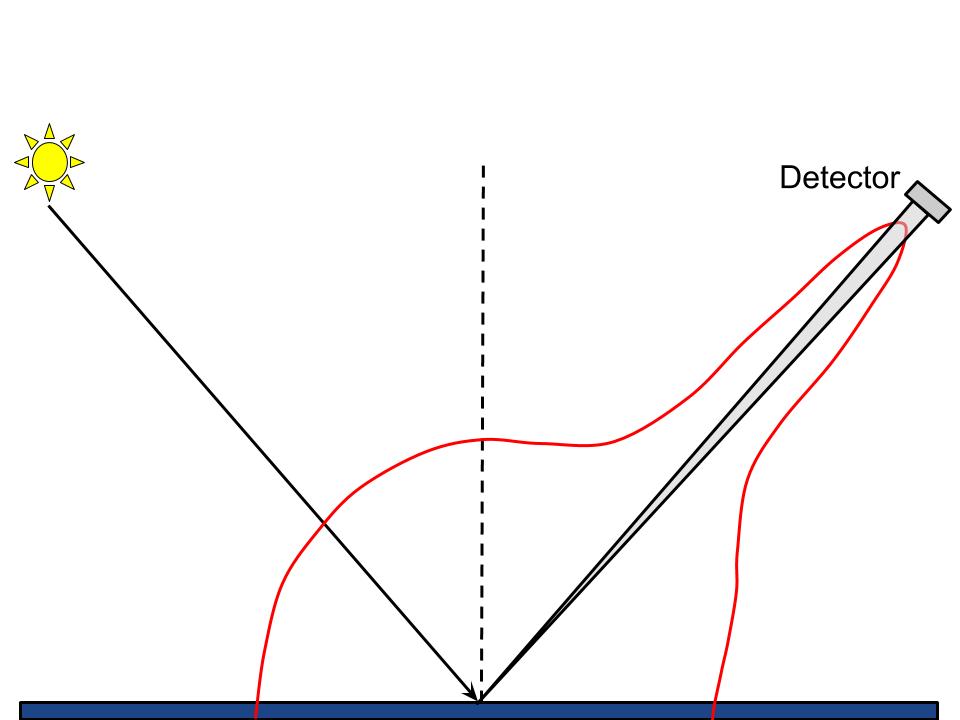

Glossmeter – Glossmeter measures the specular reflection i.e. reflection at a definite angle which is the angle of reflection. The light intensity is measured at a small range of the reflected angle. The intensity of the reflected light depends on the material and the angle of illumination. For example, non-metals (coatings, plastics) the amount of reflected light increases with increase in illumination angle whereas metals have higher reflection and less angle dependence than non-metals [2].

The glossmeter is calibrated with a black glass standard with a defined refractive index. The measurement value for this defined standard is 100 gloss units (G.U.). The sample measurements are related to the amount of light reflected from black standard and not the incident light which is why materials with higher refractive index can have measurement values above 100 G.U [3]. Since the angle of illumination influence the measurement, internationally specified handling procedures are followed to allow comparison of the measured values. To differentiate from high gloss to matte, three different ranges were defined:

Measurement of specular reflection

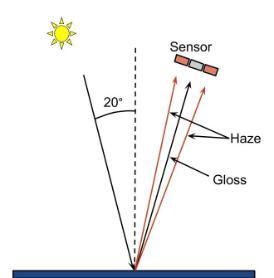

There are different viewing angles used while measuring the gloss of a surface. The direct viewing angle is at 20° to normal and the grazing angle which is at 85° gives an idea of sheen of the surface. The common gloss measurements are done at 60°.

|

Gloss Range |

60° value |

|

High Gloss |

>90 |

|

Gloss |

>70 |

|

Semi Gloss |

10 to 70 |

|

Low Gloss |

<10 |

Gloss measurement specification

- Haze

Haze or milkiness is a milky appearance of a high gloss surface caused due to microstructures (e.g. poor dispersion). The microscopic texture diffuses light with low intensity adjacent to the main direction of reflection. Majority of the incident light undergoes specular reflection which makes the surface appear highly glossy but the low intensity diffused light causes the milky haziness on top of it [1].

Haze measurement - Haze is observed in high gloss surfaces only and therefore 20° geometry is used for measurement. There are two additional sensors adjacent to the gloss detector which measure the intensity of the diffused light that causes haze. Both the specularly reflected and the scattered light are measured simultaneously and compared to measure the amount of haze. The higher the intensity of scattered light, more is the haze [2].

Measurement of Haze

In the next part we discuss about Orange peel and Mottling

Reference:

- Zeno W. Wicks, Jr. , Organic Coatings, 3rd edition, Wiley-Interscience, New Jersey, 2007.

- BYK-Gardener, QC solution for coatings and plastics, 2009 Catalog.

- R Lambourne and T A Strivens, Paint and surface coatings, 2nd edition, William Andrew publishing, US, 1999.