Volume 11 issue 2

What’s Happening at Missouri S&T:

(formerly UMR)

Short Course Dates

We will be offering "Basic Composition of Coatings" March 24-28,2014 (Spring 2014). The Basic Composition course is intended for new personnel in the coatings profession. It targets the components of coatings (resin, pigments, extenders, solvents and additives), testing and specifications, general formulation and manufacturing methods. Basic Composition is primarily a lecture course with several laboratory demonstrations.

We will be offering "Introduction to Paint Formulation" May 19-23, 2014 (Spring 2014). This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work.

We will be offering "Introduction to Coatings Composition and Specifications" July 21-23, 2014 (Summer 2014), course designed for the new coatings person in areas such as sales, marketing or production. The course was initiated by a number of raw material companies and distributors requesting a course with this format. This course is not as heavily technical as is our “Basic Composition of Coatings" and “Introduction to Paint Formulation" courses. The ?Introduction to Coatings Composition and Specifications" course is a two and a half day course which will discuss the types of coatings, the basic composition of coatings and the tests and specifications used by the industry. This course will allow the participant to gain the fundamentals needed to work in this industry and to communicate more clearly.

For more information see our web site at http://coatings.mst.edu and to register contact us at mstformulation@mst.edu or call 573-341-4419. **These courses are held on the Rolla Campus**

Online Short Course

We are offering "Introduction to the Coating Systems" online short course. This course is targeted for automotive and aviation type OEM companies. This self-paced seminar will cover the painting system from the composition of paints to the evaluation of the dry film. The pigments, resin, solvents and additives will be discussed including their influence on the coatings performance. Color measurement, surface profile, and other evaluation criteria will be related to composition. The importance of surface preparation and other manufacturing criteria will show the system complexity and each step's importance.

We are offering "Surface Defects: Elimination from Human and Process Contaminants" online short course. This course addresses many of the issues in prevention and minimization of defects. The course covers the defects caused by the coatings process, as well as human issues, including personal care product causes. Several of the surface defects are discussed – from basic principles and real world automotive and aircraft examples. The highly practical approach of this course will greatly aid the personnel involved in the painting operation to reduce and systematically approach issues.

Employment Tab

We have started an employment section for our students and companies. We have a full time job section, an intern / co-op section and a graduating and alumni students section . Please explore our section on employment on our web site. Anyone wanting to have job opening listed, please contact us at (573) 341-4419 or e-mail: svgwcc@mst.edu . You can also write to us at Missouri S&T Coatings Institute, BOM #2, 651 W. 13th St., Rolla, MO 65409-1020. Our web site is http://coatings.mst.edu

Technical Insights on coatings Science

Evaluation of Paint Adhesion

Peng Geng, Graduate Student

Missouri S&T Coatings Institute

Paint adhesion is the ability to allow the paint film to adhere to the substrate surface with sufficient strength to perform its function. Paints with good adhesion are usually more durable and showing better performance. Poor adhesion generally results in cracking and pealing. Coatings adhesion can be between the paint and the substrate or between two coatings. The evaluation of paint adhesion has been an important test for all coatings.

Therefore, due to its importance, it is critical to determine the degree of adhesion and if it meets the minimum criteria. In many cases it is only important to rank adhesion but in many applications it must be measured in a quantitative way. Not only the adhesive strength is needed but the mode of failure. Failure can occur cohesively or adhesively. Cohesive failure is when the material fails such as wood failing by ripping off a layer of the wood by the paint as it is being removed. Adhesive failure is a loss of adhesion at the interface such an between two coating of paint.

This report covers two different types of adhesion testing methods: cross-hatch adhesion test and puck pull-off tests.

CROSS-HATCH ADHESION TEST1

The cross-hatch test involves a scribe and tape, Figure 1. The cutting tool or knife cuts parallel lines in the coating to the substrate. The distance between the lines can be varied depending upon the thickness of the coatings and the requirements of the coating. The narrower the line spacing the more stress that is imparted on the coating during the scribing process. As the knife cuts through the paint it can cause delamination and chipping. After the set of parallel lines are made, a second set orthogonal to the first are made creating squares. Some testing protocols utilize a 45 degree angle to the original set of cuts to produce diamond shapes which is a more rigorous test. After a nylon brushing tape is applied over the set of squares and pressed firmly. The tape is then removed and the cuts and squares examined for chipping or delaminations. The damage is judged against pictures of damage in the ASTM protocol. This test gives a qualitative assessment of adhesion but not very quantitative.

Image1. Cross Hatch Adhesion Tester

PUCK ADHESION TEST

A more quantitative test for adhesion are the puck pull-off test. This method uses a dolly or puck which is glued to the surface of the paint and then pulled off the surface with measurement of the force needed to remove the puck. This method yields a numerical value and thus is quantitative. The Patti test is one of the most accepted methods but other removal methods have also been used. This method of direct pulling off the puck is subject to error if the substrate is deformable. A potential alternative is to remove the puck in torque mode by twisting. This puts all the force in the plane of the panel and thus allows the use of thin panels such as aluminum without the deformation issue. These two methods will now be further discussed

PATTI ADHESION TEST2

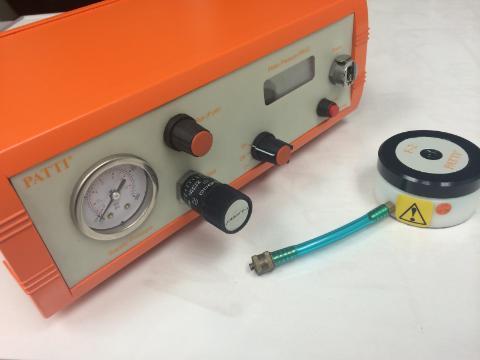

The PATTI Paint Adhesion Test is a widely used method, which measure the pull-off (commonly referred to as adhesion) strength of paints, clear coatings, ceramics, inks, and adhesives, Figure 2. The Patti adhesion test can be used to measure the force required to remove the paint from substrate.

Image 2. PATTI Adhesion Tester

This device uses compressed air or carbon dioxide to pressurize a diaphragm which lifts the puck. This supplies the tensile load to the pull-stub. By determining either the greatest perpendicular force (in tension) that a surface area can bear before a puck is detached, or whether the surface remains intact at a prescribed force (pass/fail)[1]. Failure will occur in the weakest layer of the specimen, once the pull-stub is detached from the paint surface. Then we can record the maximum pressure at the time the failure happened, and the failure can then be evaluated for mode of failure. The pressure at failure is recorded and can be converted to a value in lbs/in2.

The Patti test does suffer from errors caused by distortion of the substrate due to the force being applied perpendicular to the surface. As the substrate bows due to the pulling on the puck, a sheer plane forms which results in premature failure from the edges of the puck. Unless the substrate it 0.25 inch thick steel or thicker, the error may be present. There are other puck removal methods other than the PATTI adhesion tester. Some use hydrolic force, screw technology or testers such as an Instron unit. The Patti system is versatile and accepted by the ASTM and can be done using a portable unit for field work.

TORQUE PUCK ADHESION TEST3

A newer method which overcomes the bowing substrate issue is the Torque puck adhesion test. This method uses a torque wrench to twist the adhered stubs, a load is increasingly applied to the paint surface until it is removed the stubs from the substrate. The torque force used will be recorded and can be converted to pounds per square inch.

The torque wrench is fitted with a 9/16 inch deep socket, and is used to tighten the nut onto the aluminum pull stub which results in a torque which causes the delamination, Figure 3.

Image 3. Torque wrenchs for torque puck adhesion test

Initially, the coated substrate is lightly sanded with 320 grit paper and all dust removed. A plastic disk is applied to limit the adhesive area and the puck is glued to the center of the hole in the disk. The adhesive choice is critical with 2 ton epoxy being popular for moderate adhering coatings. For higher performance coatings a better adhesive such as 3M DP640 which has extremely good adhesion but cost is an issue. The puck adhesive is allowed to cure for 24-48 hours depending upon the adhesive chosen. It is critical that the torque wrench be held perpendicular to the substrate to avoid angular stress, Figure 4.

Image 4. Pucks glued on coated wooden substarte using 2 ton epoxy

In addition, the aluminum pull stubs shown in the photograph are reusable. After these stubs were removed from the substrate, heat them up to 600 F for an hour to burn out the adhesive attached on the stubs. Then grit blast the surface followed by a solvent wash are ready to be used again.

The force was applied to remove the aluminum pull stubs will be automatically read and displayed on the torque wrench as inch pounds. We can use the equation to convert the value to pounds per square inch.

The torque wrench test is a shearing motion instead of the traditional tensile or simple pull-off motion, and the method gives adhesion in pounds per square inch force used to remove the tabs, and the value will correspond to the degree of adhesion of the paint with the substrate without deforming the substrate.

We can say the torque wrench is a better choice in measuring the pull-off adhesion, since it has the following advantages:

- The twisting off of the tabs can ensure the test results accuracy, hence only a little substrate yield would occur.

- The operation of the torque wrench is simple.

- The torque wrench is small and light weight, without any other auxiliary or power source, making it is a good portable device.

- The thickness of the metal does not affect the adhesion values for the torque wrench test method.

- The torque wrench can use the aluminum pull-tabs provided by the PATTI adhesion test, instead of purchasing additional custom milled dollies which are normally expensive and specific.

It should be noted that for both the Patti and Torque methods, the inspection of the puck surface after removal will allow the definition of the failure mode. This should be estimated as to area and defined as either an adhesive or cohesive failure. For a two coat system, A and B, the failure modes are as follows:

- Substrate cohesive failure

- Substrate to an adhesive failure

- Coating A cohesive failure

- Coating A to B adhesive failure

- Coating B cohesive failure

- Coating B to glue adhesive failure

- Glue cohesive failure

- Glue to puck cohesive failure

- Puck cohesive failure

References:

1. ASTM D3359-02 Standard Test Methods for Measuring Adhesion by Tape Test

2. ASTM D4541 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers

3. Moon, J.K., Metz, B.A., Battelle Report, May 6, 1994, OKC-ALC

-480x360.JPG)