Volume 7 Issue 3

What’s Happening at Missouri S&T:

(formerly UMR)

Short Course Dates

We will be offering ?Basic Composition of Coatings" September 19-23, 2011 (Fall 11). The Basic Composition course is intended for new personnel in the coatings profession. It targets the components of coatings (resin, pigments, extenders, solvents and additives), testing and specifications, general formulation and manufacturing methods. Basic Composition is primarily a lecture course with several laboratory demonstrations.

We will be offering ?Introduction to Paint Formulation" May 9-13, 2011 (Spring 11) and October 10-14, 2011 (Fall 11). This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work.

We will be offering "Introduction to Coatings Composition and Specifications" July 18-20, 2011 (Summer 11), course designed for the new coatings person in areas such as sales, marketing or production. The course was initiated by a number of raw material companies and distributors requesting a course with this format. This course is not as heavily technical as is our “Basic Composition of Coatings" and “Introduction to Paint Formulation" courses. The ?Introduction to Coatings Composition and Specifications" course is a two and a half day course which will discuss the types of coatings, the basic composition of coatings and the tests and specifications used by the industry. This course will allow the participant to gain the fundamentals needed to work in this industry and to communicate more clearly.

For more information see our web site at http://coatings.mst.edu/index.html and to register contact Catherine Hancock at cemv26@mst.edu or coatings@mst.edu or call 573-341-4419. **These courses are held on the Rolla Campus**

Technical Insights on Coatings Science

Moisture Scavengers for Urethane Coatings

Cynthia Riddles, Graduate Research Student, Missouri S&T

Moisture in urethane coatings can be extremely detrimental. In two component solvent borne systems, atmospheric moisture reacts with the isocyanate and releases CO2 which causes foam in the coating, and takes up part of the isocyanate needed to react with the polyol. In moisture cure urethanes, moisture in the can will cause the isocyanate capped polymer chains to begin the curing process, by first forming amines which then react quickly with other isocyanate terminated polymer chains increasing the viscosity and possibly gelling the coating in the can.

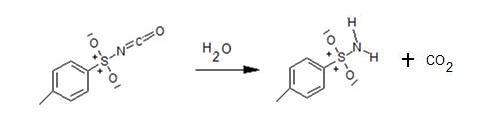

There are two popular moisture scavenging methods which can be utilized to eliminate the problems caused by the reaction of water with the isocyanate; these are liquid chemicals and dry desiccant types. Liquid chemicals such as PTSI (p-toluenesulfonyl isocyanate) available from the Van De Mark Chemical Company,1 reacts quickly with water and produces CO2 and the p-toluenesulfonamide, as shown below.

|

Figure 1. Formation of p-toluenesulfonamide

A second type of moisture scavenger which can be used is molecular sieves (zeolites), such as Sylosiv 3 A from Grace Davison.2 This type of desiccant traps very small molecules such as water due to the pore size of 3 Angstroms. Crushed molecular sieves are able to be added into coatings formulations and are dispersible. It should be noted that they are able to pick up moisture from the air so they need to be kept anhydrous or activated prior to incorporation.

Moisture in urethane coatings comes from many sources; solvents, pigments, the resins, the air, and even the surface to which they are being applied. For many formulations, addition of a moisture scavenger can help eliminate the problematic moisture, or trap it and prevent the reaction with the isocyanate. These can help cut the cost of the formulation by protecting the isocyanate from being destroyed by reacting with the water.

References

- Van De Mark Chemical. http://www.vdmchemical.com/pdf/VDM-PTSI.pdf

- W.R. Grace & Company. http://www.grace.com/engineeredmaterials/ProductsAndApplications/Coatings/MoistureScavengingPowders/MolecularSievePowders.aspx

Alliance for Advanced Coatings Research Donation

The Alliance for Advanced Coatings Research made a donation of several pieces of equipment which will aid in coatings research and education at the Missouri S&T Coatings Institute. The Alliance was a non-profit research group and their equipment was transferred to the Institute. Harvest Collier was responsible for the transfer. We wish to thank Dr. Collier and the Alliance for Advanced Coatings Research for the donation. The following is a list of the equipment:

- Wavescan GB-4800

- Haze-Gloss with Motor GB-4606

- Color-View 9000

- Gradient Oven TB-2615

- The Color Sphere 8850

- Falling Sand Abraser AG-1046

- Micro-Tri-Gloss

- Micro-Gloss 45 GB-4535

- ICI Cone & Plate Viscometer

- Conductivity Meter CB-1722

- Electrode CB-1710

- Wirecator Set AR-4100

- Dry Time Recorder

- QUV Chamber

- QFog corrosion Chamber

It should be noted that much of the equipment was originally donated in 1993 to the Alliance by Weskem-Hall, Inc. a Byk-Gardner distributor. All of the equipment is in excellent condition.