Volume 14 Issue 4

WHAT’S HAPPENING AT MISSOURI S&T (FORMERLY UMR):

SHORT COURSE DATES

We will be offering "Introduction to Paint Formulation" August 13-17 (Fall 2018). This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work.

For more information see our web site at http://coatings.mst.edu and to register contact us at mstformulation@mst.edu or call 573-341-4419. **These courses are held on the Rolla Campus**

ONLINE SHORT COURSE

We are offering "Introduction to the Coating Systems" online short course. This course is targeted for automotive and aviation type OEM companies. This self-paced seminar will cover the painting system from the composition of paints to the evaluation of the dry film. The pigments, resin, solvents and additives will be discussed including their influence on the coatings performance. Color measurement, surface profile, and other evaluation criteria will be related to composition. The importance of surface preparation and other manufacturing criteria will show the system complexity and each step's importance.

We are offering "Surface Defects: Elimination from Human and Process Contaminants" online short course. This course addresses many of the issues in prevention and minimization of defects. The course covers the defects caused by the coatings process, as well as human issues, including personal care product causes. Several of the surface defects are discussed – from basic principles and real world automotive and aircraft examples. The highly practical approach of this course will greatly aid the personnel involved in the painting operation to reduce and systematically approach issues.

EMPLOYMENT TAB

There are no current job openings available. Anyone wanting to have job opening listed, please contact us at (573) 341-4419 or e-mail: mstformulation@mst.edu . You can also write to us at Missouri S&T Coatings Institute, BOM #2, 651 W. 13th St., Rolla, MO 65409-1020. Our web site is http://coatings.mst.edu

TECHNICAL INSIGHTS ON COATINGS SCIENCE

Rheology of Coatings Part III

Methods for Measuring Viscosity

Abbie Braden, Graduate Research Assistant, Missouri S&T Coatings Institute

Viscosity affects the way paint is applied, the dry time, and film thickness. Therefore it makes sense that customers have different preferences on viscosity based on the use of the paint. After paint is made, it must meet viscosity specifications before it is sold. This quality check process is universal with all paint manufacturers, however there are several different methods that may be used to measure viscosity. The ideal paint will exhibit a thixotropic behavior, where over an increase in shear, it will first decrease in viscosity, then at a certain point increase back to the starting viscosity.

Flow Cups

Flow cups measure how quickly a fluid flows through an orifice with a designated diameter under gravitational forces and hydrostatic pressure. The time it takes for the cup to empty, or efflux time, is typically measured in seconds and from this, the kinematic viscosity can be calculated.

Where ν is kinematic viscosity, η is shear viscosity, and ρ is density

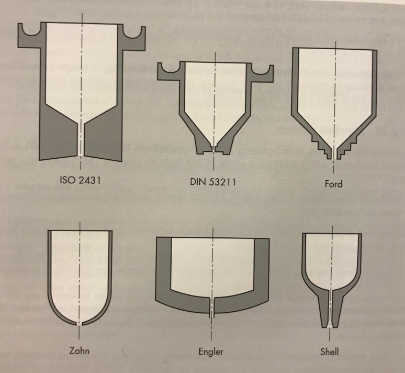

There are many different types of flow cups such as the Zahn, Ford, and ISO cups. The main difference in these are the dimensions and shape of the cup. Each one may come with a variety of orifice diameters. For example, a Zahn cup has varieties from #1- #5 where the larger numbers are used with materials that are more viscous.

Types of Flow Cups1

Mezger, The Rheology Handbook. Figure 10.1

There are some possibilities for uncertainty when measuring viscosity with flow cups. If there are any particles or bubbles in the paint, they will affect the flow out of the orifice and cause an error in the reading. It is also a somewhat relative measurement, as the timer may be stopped at different speeds depending on the technician that is taking the reading. It is difficult to determine the thixotropic behavior of a paint with this method too, as the paint may not flow unless there is shear applied.

Stormer-Krebs Viscometer

A stormer viscometer uses a spindle with two paddles to measure the resistance, or torque, of the fluid to the paddles when they are rotated at a certain velocity. The paddles and shaft typically have dimensions of 24mm x 8mm. This torque is given in Krebs Units, or KU. The paddle is lowered into the coating to a designated depth and begins to spin, calculating data. This method is considered a relative measurement due to the possibility of the spindles causing turbulent flow, which means shear rate cannot be calculated. Like the flow cups, it is not possible to analyze paint under thixotropic conditions with this viscometer; though there is shear applied to the paint when stirred, it is a constant shear and does not create a dynamic curve to represent thixotropy.

Brookfield KU-1 Viscometer2

Cone-and-plate

Cone and plate viscometers utilize a flat, circular cone which is placed a narrow distance from a stationary plate. The cone begins to spin and creates shear against the coating, very similar to the two plate model that is often used to describe the relationship between shear and viscosity. The cone can be either pointed, with the tip touching the plate, or truncated with a distance between the cone and the plate. This method is often preferred because it uses a very small amount of the sample, creates constant shear, and eliminates most air bubbles due to the very small gap between the plate and cone. However, this method can only be used up to a maximum particle size in order to avoid abnormalities in the flow. These types of viscometers are better at measuring thixotropy, as they can measure at high shear during spinning, and after the shearing stops.

Brookfield CAP 2000 Viscometer2

Rheometer

The ideal instrument for measuring viscosity would be a rheometer. Unfortunately these are not used often in industry due to their price, but more and more companies are starting to see that the benefits of these instruments could be well worth the prices. They measure the viscosity of a liquid over a programmed range of shear. Therefore, the true behavior of the paint is known, and manufacturers as well as customers will have a better understanding of how a paint will respond to certain application methods. For research and development uses, a programmable rheometer would be the best option. This way, the amount or type of shear can be adjusted to fit the type of paint that is being analyzed. There are also non-programmable options that are less expensive and may better fit the needs of quality control.

Rheometer Used by Missouri S&T Chemistry Department

Bubble Viscometer

These viscometers are very simple and not often used in industry today. They consist of a set of tubes filled with liquids that have known viscosities. The paint would be placed in a similar tube, and the two would be inverted simultaneously. An air bubble would then begin to travel up the tube and whichever tube has the fastest bubble has a lower viscosity. This is repeated with different standard tubes until one closely matches the speed of the bubble in the paint. This method should be used in conjunction with one of the others mentioned above, as it provides more of a quick comparison than an actual value.

Bubble Viscometer

The tube on the left has a faster moving bubble and therefore a lower viscosity.

References

- Mezger, T. G. The Rheology Handbook, 2nd ed.; Vincentz Network, 2006, 171-280.

- Brookfield Engineering