VOLUME 15 ISSUE 3

WHAT’S HAPPENING AT MISSOURI S&T (FORMERLY UMR):

SHORT COURSE DATES

We will be offering "Introduction to Paint Formulation" May 20-24 (Spring 2019). This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work.

We are also offering a new course, "Coatings Composition and Properties for Sales and Marketing Personnel" March 25-27 (Spring 2019). This course is designed for those in the industry who buy and/or sell raw materials into the coatings market, as well as those who buy or sell coatings or simply use coatings. The course is intended to help the newer person in the field gain a better understanding of the science behind paint. For more information, including course times and fees, click the course name above.

For more information see our web site at http://coatings.mst.edu and to register contact us at mstformulation@mst.edu or call 573-341-4419. **These courses are held on the Rolla Campus**

ONLINE SHORT COURSE

We are offering "Introduction to the Coating Systems" online short course. This course is targeted for automotive and aviation type OEM companies. This self-paced seminar will cover the painting system from the composition of paints to the evaluation of the dry film. The pigments, resin, solvents and additives will be discussed including their influence on the coatings performance. Color measurement, surface profile, and other evaluation criteria will be related to composition. The importance of surface preparation and other manufacturing criteria will show the system complexity and each step's importance.

We are offering "Surface Defects: Elimination from Human and Process Contaminants" online short course. This course addresses many of the issues in prevention and minimization of defects. The course covers the defects caused by the coatings process, as well as human issues, including personal care product causes. Several of the surface defects are discussed – from basic principles and real world automotive and aircraft examples. The highly practical approach of this course will greatly aid the personnel involved in the painting operation to reduce and systematically approach issues.

EMPLOYMENT TAB

Anyone wanting to have job opening listed, please contact us at (573) 341-4419 or e-mail: mstformulation@mst.edu . You can also write to us at Missouri S&T Coatings Institute, BOM #2, 651 W. 13th St., Rolla, MO 65409-1020. Our web site is http://coatings.mst.edu

TECHNICAL INSIGHTS ON COATINGS SCIENCE

Density

Ashish Zore, Graduate Research Assistant, Missouri S&T Coating Institute

The density of a substance is its mass per unit volume. It’s often denoted by a symbol ρ (the lower case Greek letter rho). Mathematically, density is defined as ρ = M/V, where M is the mass and V is the volume. In U.S. the units for density is often pounds per gallon. Here, a standard volume of 1 gallon is used to report the density values. So water, for example, has a density or a weight per gallon of 8.34 pounds/gallon at 4°C. Other countries use metric units such as grams/ml or kg/liter for density. According to the metric definition, 100 grams of water will fill a volume of 100 cm3 at 4°C. Therefore, water has a density of 1.0 grams/cm3 at 4°C. The density of a material can have different densities depending on the purity, packing, etc. Among the known elements, Osmium and Iridium are the densest at standard condition for temperature and pressure. Density of materials can change with temperature or pressure. The density increases with increasing pressure while increasing temperature can increase or decreases the density. For example, density of water increases from 0 °C to 4 °C but it decreases as we increase temperature beyond 4 °C.

Importance of density in paint

In formulating paint, determining the density of the wet paint is required for conversion of weight into a volume unit. While manufacturing paint, the raw materials are measured in weight units to control the process but the finished product is sold in volume units. A common problem that can occur during manufacturing is foaming. Excessive foaming can reduce the density of the paint by incorporating low density air in to the mixture. One can easily measure the density of the paint and find out if there is any foaming issue.

Dry film density is a bit more complicated to measure. One can get a good approximation of dry film density based on the density of the wet paint, the density of the solvents and the weight of the solids. This calculation method cannot account for the shrinkage of the film during cross-linking and loss of reaction volatiles which occur especially in thermoset systems.

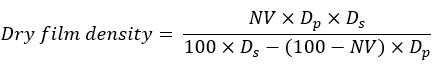

The general equation is:

Where NV = percent of Non-volatile solids measured per standard method, Dp = density of the wet paint measured per standard method, and Ds = density of the solvent (a calculated average of all solvents present).

For example, if you have a paint that measured at 45.5 percent solids and a wet paint density of 9.8 pounds/gallon and a solvent density of 8.2 pounds/gallon, the calculation for dry film density will be [45.5 × 9.8 × 8.2] / [100 × 8.2 – (100-45.5) x 9.8] = 12.79 pounds/gallon.

Solvent mixtures are often used in paints especially solvent borne ones. Mixing two or more solvents of different densities results in a mixture having weight average density. However, there are exceptions, for example, a mixture of water and ethanol. When 250 ml of ethanol is mixed with 250 ml of water then the resulting solution has volume of 480 ml and not 500 ml as one would expect. Here, the volumes cannot be simply added together. Hence, the actual density is higher than weighted average density of the mixture and needs to be measured. By measuring a mixture of solvents based on their use in a coating an accurate density of the solvent blend can be obtained.

How to measure density

Density of paints is often measured using a density cup or a pycnometer. In U.S. it is often referred as a weight per gallon cup. All the density cup designs work the same way having a precise empty volume with small hole in the lid to allow for excess paint to ooze out. The following standards are used in the industry and labs for measuring the density: D1475—13, ISO 2811 & DIN 53 217. Fig. 1. Shows a picture of density cup that is compliant with the above 3 standard and is used for measuring the density of liquid paint. For very high level of accuracy, sophisticated instruments like Rudolph DDM 2911 density meter is used. It offers accurate measurement to 0.00005 g/cc. Such instrument are useful for high level of work in Pharmaceutical, Chemical, Beverage, Fragrance, and Petroleum industries. One such requirement for high level of accuracy in density is for determining the precise concentration of ethanol in alcoholic drinks manufactured in distilleries.

Fig. 1. Picture of density cup (top) and Rudolph DDM 2911 density meter (bottom).

Reference:

- https://www.britannica.com/science/density

- D1475—13 Standard Test Method for Density of Liquid Coatings, Inks, and Related Products.