Volume 6 Issue 2

What’s Happening at Missouri S&T:

(formerly UMR)

Summer 2009 Short Course - "Introduction to Coatings Composition and Specifications"

** Register Today - Some Spaces Still Available!!!**

This summer we will be offering "Introduction to Coatings Composition and Specifications" July 20-22, 2009 in St. Louis, MO, a course designed for the new coatings person in areas such as sales, marketing or production. The course was initiated by a number of raw material companies and distributors requesting a course with this format. This course is not as heavily technical as is our “Basic Composition of Coatings" and “Introduction to Paint Formulation" courses. The ?Introduction to Coatings Composition and Specifications" course is a two and a half day course which will discuss the types of coatings, the basic composition of coatings and the tests and specifications used by the industry. This course will allow the participant to gain the fundamentals needed to work in this industry and to communicate more clearly. More information can be found at the above links, on our website at http://coatings.mst.edu/index.html, by emailing coatings@mst.edu or by calling 573-341-4419.

Fall Short Course Dates

This fall we will be offering ?Basic Composition of Coatings" September 21-25, 2009 . The Basic Composition course is intended for new personnel in the coatings profession. It targets the components of coatings (resin, pigments, extenders, solvents and additives), testing and specifications, general formulation and manufacturing methods. Basic Composition is primarily a lecture course with several laboratory demonstrations. For more information see our web site at http://coatings.mst.edu/index.html and to register contact Michael Van De Mark at coatings@mst.edu or call 573-341-4419. **This course is held on the Rolla campus**

This fall we will be offering ?Introduction to Paint Formulation" November 2-6, 2009 . This course is intended to give the person a fundamental knowledge of how to approach a starting formulation and troubleshoot it. This course involves both lecture and laboratory work. For more information see our web site at http://coatings.mst.edu/ and to register contact Michael Van De Mark at coatings@mst.edu or call 573-341-4419. **This course is held on the Rolla campus**

Technical Insights on Coatings Science

Edible Coatings on Cut Fruit

Bradley Porter, Undergraduate coatings major, Missouri S&T Coatings Institute doing research on water reducible coatings. The paper presented here is his coatings term paper.

Introduction

The market for fresh-cut produce comprised approximately 10% of all U.S. produce sales in 20031, making it a sizable market to target for advancements. An advancement that can be capitalized upon in this market involves increasing the life of the product sold to the consumer. Fresh-cut fruit has the same problems with shelf life caused by environmental exposure that non-cut produce has, but the rate at which those problems occur is accelerated due to the fruit being exposed because it lacks a natural protective coating.

Just as non-cut fruit has a natural and sometimes artificial coating to protect it; fresh-cut fruit can also have a coating applied to the surface of the fruit to inhibit exposure to undesired amounts of ambient substances. By increasing the shelf-life of fresh-cut fruit, produce distributors can market the product as a “better” product with a longer shelf-life, fresh-cut fruit that doesn’t brown as readily as competitors’, and/or that the product is protected from bacterial growth. These enhanced features allow the distributor to have the product for longer durations of time on the shelf for sale, or can allow for longer durations of time in transit.

Coating Features

Multiple properties/features can be targeted for coatings on fresh-cut fruit. The most common goal of edible coatings on fresh-cut fruit is to decrease the rate at which oxygen, carbon dioxide, water, and/or aromatic compounds enter and exit the fruit. By decreasing the amount of oxygen present in the fruit and increasing the concentration of carbon dioxide, it is possible to decrease the rate of ethylene production, the rate of ripening, and the rate of oxidation of the fruit that causes the fruit to brown1. By controlling the entrance and exit of aromatic compounds, the taste of the fruit can be maintained by not allowing foreign compounds entrance and by limiting the loss of aromatic compounds that the fruit originally contained. The control over the aromatic compounds is useful in maintaining an uncorrupted taste of the fruit, while modifying oxygen, carbon dioxide, and water levels are necessary in maintaining the texture and proper ripeness of the fruit for sale and consumption.

Another useful feature of coatings for fresh-cut fruit is one that contains anti-microbial substances (lemongrass and oregano oil). 4 The use of anti-microbial additive in the coating on fruit is to limit the access of the bacteria to a reproduction-rich environment (the inside of the fruit), and limit number of unwanted bacteria that is ingested by the consumer. While this can be a selling point to certain individuals who are conscious of the potential health hazards related with ingesting harmful bacteria, it could harm sales with some customers that may be worried about potential side-effects caused by the coating.

Coatings commonly used on cut fruit have film thicknesses within the range of 40-160 micrometers (1.57-6.3 mills). The anti-microbial coatings mentioned, lemongrass and oregano oil, were found to be the most effective coatings at concentrations of 1.5% w/w and 0.5% w/w respectively.4 Anti-browning coatings containing anti-oxidants are used in concentrations of 0.5-2% w/v.2,3 Each of these coatings should have good adhesion to insure substrate protection. The coatings should also have moderate abrasion resistance that should be sufficient to provide protection while handling and transporting the product, but weak enough to not hinder the consumption of the product by the consumer. The coatings should all be waterborne to prevent corruption of the taste of the fruit by common solvents. Most coatings utilized in this market would be well served to be as transparent as possible in order to not limit the number of fruits that the coating could be applied to due to the presence of color. In seeking a coating that is not markedly noticeable to the consumer, it is important to limit the amount of hide provided by the coating.

Application

Edible coatings on fresh-cut fruit are commonly applied in one of three methods: immersion, spraying, or brushing. The most common method of application is immersion, or dipping. Immersion is the ideal method of application of the coating to fresh-cut fruit due to the ability to coat large amounts of fruit in a relatively short duration of time (~2 minutes).2,3,4 After being immersed, the coating can then be allowed to drip dry before packaging. While immersion may not provide a defined consistent coating thickness, it does provide the best method for insuring full coverage of the fruit.

Due to the relatively low viscosity of these coatings, spraying as a method of application is a viable option. Spraying is more labor intensive than immersion, and has the added disadvantage of the cost of the spraying apparatus and the increased amount of time necessary to insure full coverage of the fruit. These added costs related to the spraying method of application may have an effect on the ability of the coated product’s price to compete with other products.

Brushing does not require the potentially prohibitive cost of the spraying apparatus, but it too is labor and time intensive. There are no apparent reasons to justify brushing in favor of immersion for applying an edible coating to fresh-cut fruit. It offers no cost advantage, while presenting disadvantages in time needed for application, and the amount of labor that would be required to brush on a coating that could be applied in minutes to the same amount of fruit with a single immersion.

Common Coatings

There are many coatings that are used to coat fruit and can be classified as “edible”, but most can be separated into the following categories: hydrocolloids, lipids, composites, and bilayers. To accompany these categories of coatings there also exist multiple additives that can be utilized to retain the desired texture, color, flavor, and scent of the fruit being coated.

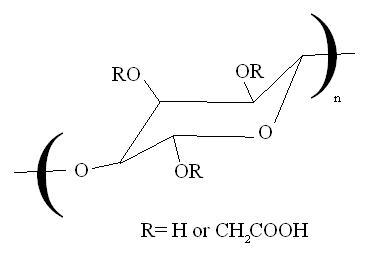

Hydrocolloid coatings are good gas barriers for fresh-cut fruit. They are heterogeneous mixtures of proteins or carbohydrates with suspended particles in water. 1 Proteins and polysaccharides (polymeric carbohydrates) are commonly used in these types of coatings.1 To increase the capability of the coating to reduce water vapor penetration; the hydrocolloid can be mixed with lipids (composite coating) or coated over by lipids (bilayer). 1 If proteins are used in the hydrocolloid they can have the added benefit of increasing the protein content, making the fruit marketable as “higher in protein” than “normal” fruit. Hydrocolloids with whey protein, calcium caseinate protein, or carboxymethyl cellulose (figure 1) can introduce anti-oxidation capability (anti-browning) which can be useful in maintaining the original color of the fruit or perhaps even marketing the enhanced antioxidant content of the fruit. 1

|

Figure 1: Carboxymethyl cellulose 5

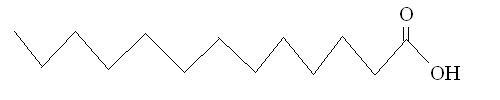

As stated in discussion of hydrocolloid coatings, lipids (Figure 2) make for improved water vapor barrier coatings. By maintaining preferred water content of the fruit, the coating can help maintain the proper texture of the fruit. A downside for stand-alone lipid coatings is their relatively poor mechanical integrity1, thus strengthening the argument for including lipids in a hydrocolloid mixture coating.

|

Figure 2: Long chain saturated fatty acid

Composite coatings are formed by mixing two individual coatings into a homogenous or evenly mixed system, and then applying them as a single coating. 1 These coatings can be useful when features of multiple coatings are necessary, the quality of those features can be maintained through mixing them into a single coating, and the simplicity of a simple coating is deemed advantageous (coating application and dry time is decreased).

Bilayer coatings are formed by applying two independent coatings, one on top of the other. 1 These types of coatings can be useful in the case that forming a composite coating of the two independent coatings causes the desired properties of the independent coatings to be compromised. Using bilayer coatings can be seen as a disadvantage due to the increased amount of time necessary to coat the fruit, since the first coating must be allowed to dry before the second coating is applied.

Testing

There are two common quantitative types of testing an edible coating, and one commonly utilized qualitative. First, the coating alone can be quantitatively tested for gas permeability properties and mechanical properties. Another quantitative method would test the coating when it has been applied to the substrate, fresh-cut fruit. Testing of the coating on the fruit would provide more useful data in terms of describing the effectiveness of the coating at performing its specified duties on the surface it was formulated to be applied to. The qualitative testing involves the utilization of potential-customer testing, and utilizing their observations to improve or modify the coating formulation.

Water vapor permeability can be measured with respect to the level of relative humidity of the environment that the coating is exposed to. 1 Whether the fruit is in an arid, humid, or moderate environment, it is necessary to understand just how effective the coating will be in preventing water loss or water gain in the respective environments. To insure the most effective edible coating for preventing water permeability, it is necessary for the coating to have a hydrophobic component such as a lipid. 1 Lipids are capable of forming effective barriers to prevent penetration of water vapor through the coating (in or out).

Concerns about other gases entering and leaving the fruit have been stated previously. Too much oxygen being present in fruit can cause browning and accelerate ripening.3 Increased carbon dioxide concentrations can decrease the rate of ripening.1 Flow of aromatic compounds in and out of the fruit can cause the flavor and/or scent of the fruit to be compromised. So a coating that blocks oxygen from entering and prevents aromatic compounds and carbon dioxide from leaving would be ideal. To test the permeability of the coating, a film can be formed and used to separate two volumes. The substances in question can be introduced into one volume, and their concentrations on the opposite side of the coating can be measured and compared to the amounts introduced.

Concerning the testing of the coating applied directly to the fruit, water loss can be measured as a change in mass of the coated fruit.1 Deformation texture of the coated fruit can be measured using a standardized applied force. For the purpose of testing antimicrobial coatings, the population of bacteria present on the coated fruit can be measured after certain durations of time after a known population was introduced. Color retention of the coated fruit can be measured using a colorimeter (to determine the presence or lack of browning). 1 Aromatic compounds that escape the coated fruit can be analyzed and quantified using special gas chromatography techniques (solid phase microextraction) to determine the effectiveness of a gas barrier coating. 1

Perhaps the most important testing is done by the potential customers of the coated fruit product. Their observations are important in determining the potential for success of the product. For instance, a coatings professional may easily notice the different appearance, taste, smell, or texture of a coated piece of fruit, but does the average consumer notice? If the consumer does notice, how do they feel about it?

Conclusion

Ultimately the most important question to be answered is “will this sell?” If for whatever reason(s) the customer doesn’t like the fruit or other produce that your coating has been applied to, in contrast to the uncoated produce, there will be a problem selling it to them. Even if the formulator makes the “best” coating for the produce possible, if the customers don’t like the way it looks, the way it tastes, the way it feels, or a number of other potential shortfalls, the fact that it may be scientifically better than any other coating at achieving the desired properties won’t matter because it won’t sell. Through the use of skilled marketing and the proper education of the consumer, producing a successful coating based on performance and sales should prove to be advantageous to all parties involved in this market by producing a product that remains in a marketable condition for a longer duration of time.

References

1. G.I. Olivas and G.V. Barbosa-Canovas. “Edible Coatings for Fresh-Cut Fruits.” Critical Reviews in Food Science and Nutrition. 45 (2005) 657-670

2. G. Oms-Oliu, R. Soliva-Fortuny, O. Mart´in-Belloso. “Edible coatings with antibrowning agents to maintain sensory quality and antioxidant properties of fresh-cut pears.” Postharvest Biology and Technology. 50(2008) 87-94.

3. G. Oms-Oliu, R. Soliva-Fortuny, O. martin-Belloso. “Using polysaccharide-based edible coatings to enhance quality and antioxidant properties of fresh-cut melon.” Swiss Society of Food Science and Technology. 41 (2008) 1862-1870.

4. Mar´ia A. Rojas-Gra¨u, Rosa M. Raybaudi-Massilia , Robert C. Soliva-Fortuny, Roberto J. Avena-Bustillos , Tara H. McHugh, Olga Mart´in-Belloso. “Apple puree-alginate edible coating as carrier of antimicrobial agents to prolong shelf-life of fresh-cut apples.” Postharvest biology and Technology. 45 (2007) 254-264.

5. Chaplin, Martin. “Carboxymethylcellulose (CMC)”. Water Structure and Science. Updated 22 June 2008. Accessed 11 May 2009.